Mixed volume of material:10L-5000L

Mixer power:

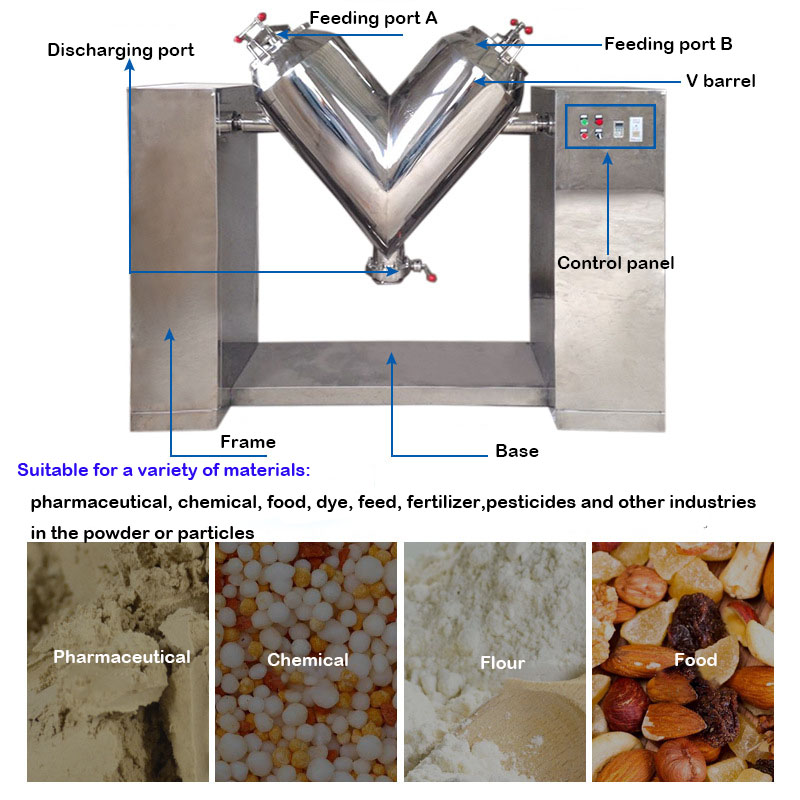

V mixer machine applied to good liquidity dry powder and granular material mixing in chemical industry, food industry. This machine mixing cylinder structure special, high efficiency, no blind angle,material adopt stainless steel, wall polishing treatment, nice appearance,equally mixing.

| Model | Total Volume | Effective Volume | Rotary Speed | Power | Weight |

| JHV-50 | 50 | 25 | 23 | 0.4 | 200 |

| JHV-100 | 100 | 50 | 22 | 0.55 | 300 |

| JHV-300 | 300 | 150 | 20 | 0.75 | 500 |

| JHV-500 | 500 | 250 | 18 | 1.5 | 700 |

| JHV-1000 | 1000 | 500 | 15 | 3 | 1800 |

| JHV-1500 | 1500 | 750 | 15 | 4 | 2300 |

| JHV-2000 | 2000 | 1000 | 14 | 5.5 | 3400 |

| JHV-3000 | 3000 | 1500 | 14 | 5.5 | 4250 |

| JHV-4000 | 4000 | 2000 | 14 | 7.5 | 5500 |

| JHV-5000 | 5000 | 2500 | 14 | 7.5 | 6000 |

1. Fast mixing of dry powder or small granules with good flowability in food and chemical industry

2. Mixing chamber volume: 50-2000L; Lab model: 2L-50L.

3. GMP design

4. Agitator can be equipped to strengthen the mixing effect

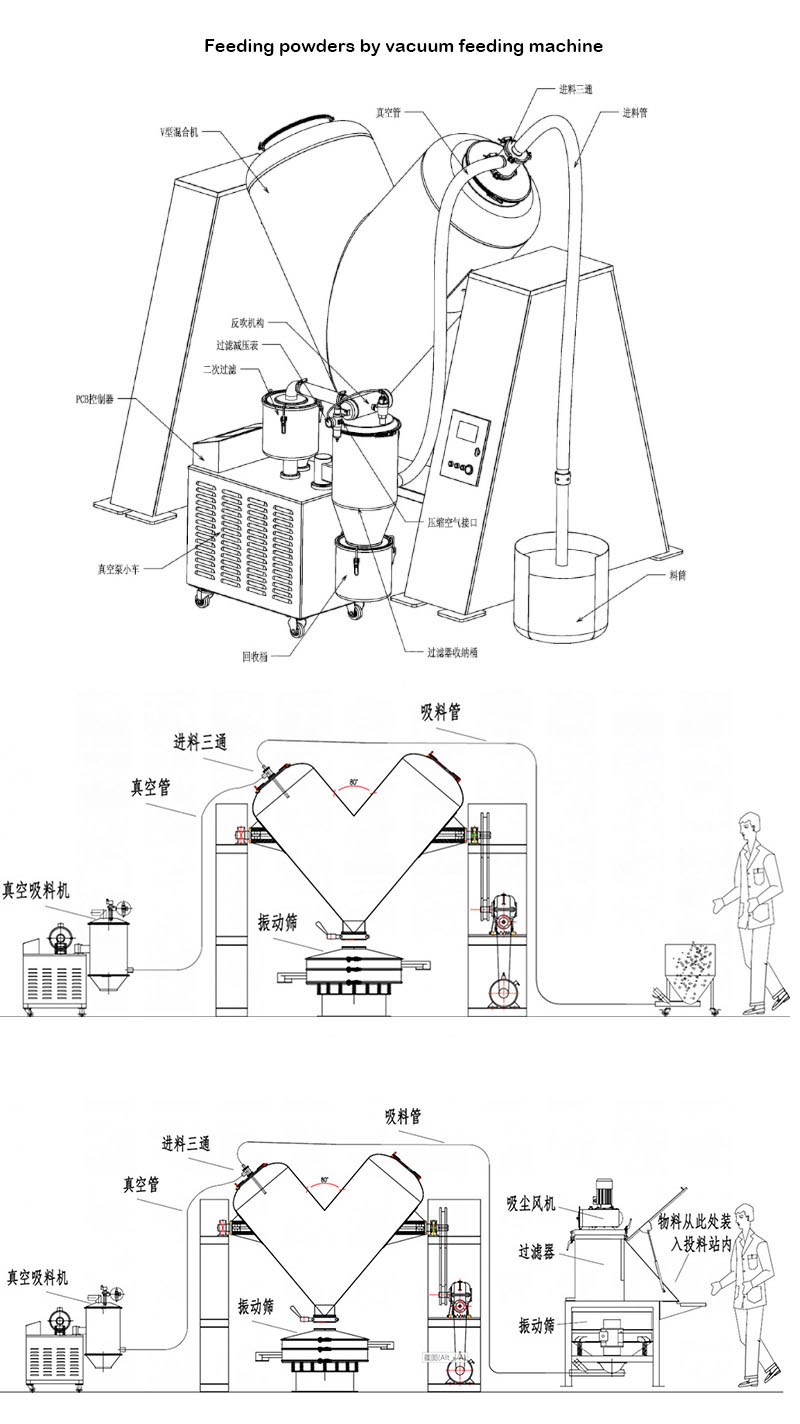

5. Can work with vacuum conveyor to achieve automatic feeding and prevent dust

The cylinder is designed as V-shape, mixing blade can be mounted inside the cylinder. Materials are lifted, dripped, mixed with the rotation of cylinder during operation, therefore no mixing dead zone.

1. Mirror polished of inner and outer shell to meet GMP standard.

2. No blind angle in the V-shells, no accumulation of materials, high speed I-bar, efficient and short mixing time.

3. Mixing uniformity can reach 99%

4. Plate valve is equipped for discharging

5. Fully integrated motors and controls

6. Can work with vacuum feeding system to create dust-free working condition.

Mixers can be customized with 304 stainless steel, 316L stainless steel and other materials, and different materials can also be used in combination.

When selecting equipment materials, distinguish between: parts in contact with materials and parts not in contact with materials.

The inside of the mixer can also be targeted to add functional coatings or protective layers such as anti-corrosion, anti-adhesion, isolation, and wear resistance.