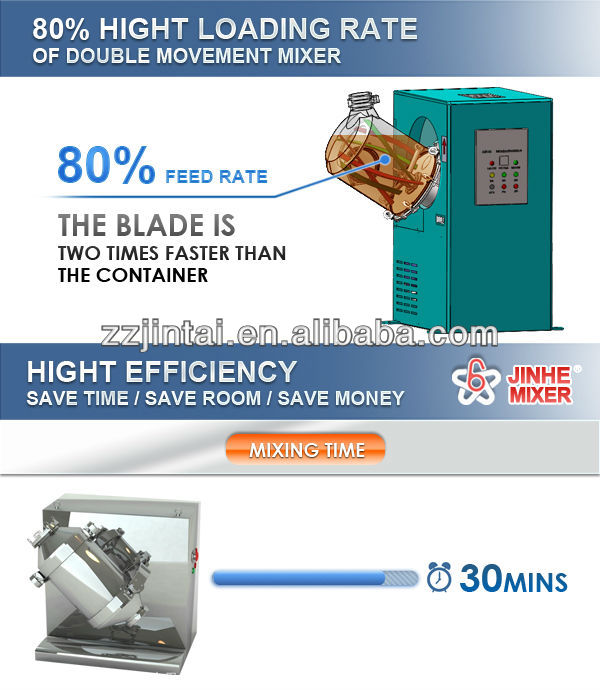

Mixed volume of material:3L~110L

Mixer power:1.5KW

| Model | Barrel Capacity (L) |

Max Capacity (L) |

Max Weight (kg) |

Barrel Speed (r/min) |

Blade Speed (r/min) |

Motor Power (kw) |

Size (mm) |

Weight (kg) |

| JHN-15 |

3~18 | 2~13 | 18 | 23 | 60 | 0.55 | 1045*600*990 | 100 |

| JHN-55 |

20~55 | 20~44 | 55 | 22 | 55 | 0.75 | 1200*780*1250 | 300 |

| JHN-110 |

60~110 | 48~88 | 100 | 20 | 49 | 1.5 | 1300*820*1400 | 500 |

| JHN-200 |

200 | 160 | 200 | 16 | 32 | 3.0 | 1500*960*1800 | 700 |

| JHN-600 |

600 | 480 | 600 | 12 | 24 | 4.0 | 1900*1500*2100 | 1200 |

| JHN1000 |

1000 | 800 | 1000 | 10 | 20 | 5.5 | 2400*1900*2800 | 1800 |

|

|

Barrel Capacity (L) |

Max Loading Weight(kg) |

Barrel Speed (r/min) |

Blades Speed (r/min) |

Motor Power (kw) |

Size |

|

JHN-15 |

11、15、18 |

35 |

23 |

60 |

0.37 |

1045*600*990 |

|

JHN-55 |

30~55L |

60 |

22 |

55 |

1.1 |

1200*780*1250 |

|

JHN-110 |

60~110L |

100 |

20 |

49 |

1.5 |

1300*820*1400 |

Transportation: