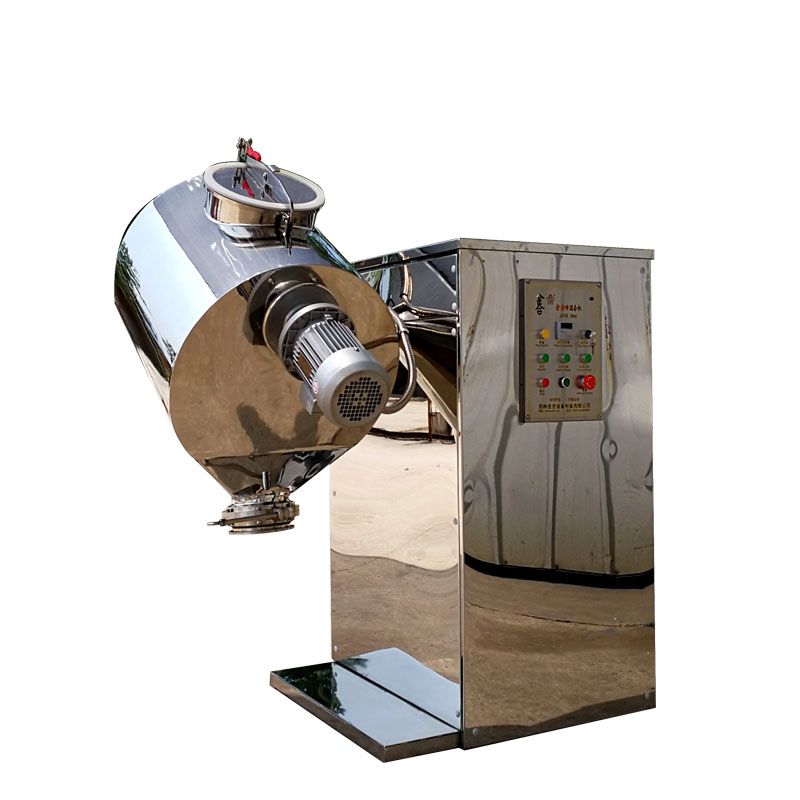

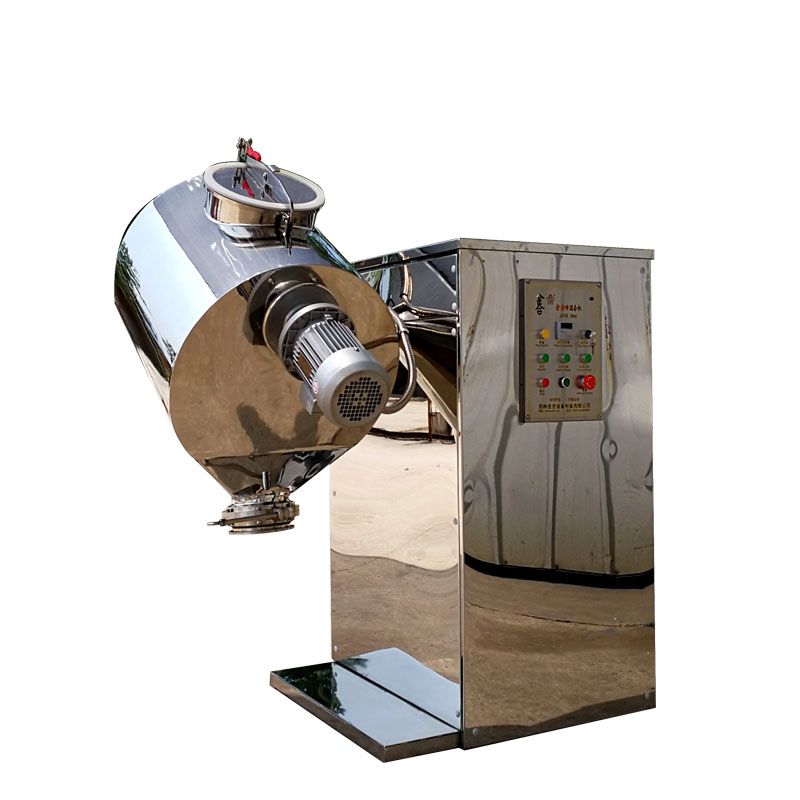

Mixed volume of material:50-5000L

Mixer power:

1. Application: Dry Powder, Pesticide, Animal Fodder, Compound Fertilizer, Feed Additive,Verterinary Drug,Silica Sand,Cenment etc

2.The dry powder ribbon mixer, Material can be both Stailess steel.

3. Ribbon mixer, can also be used to mix thick material.

4. Here we provided mixer capacity from 50L-5000L

Technical Parameters

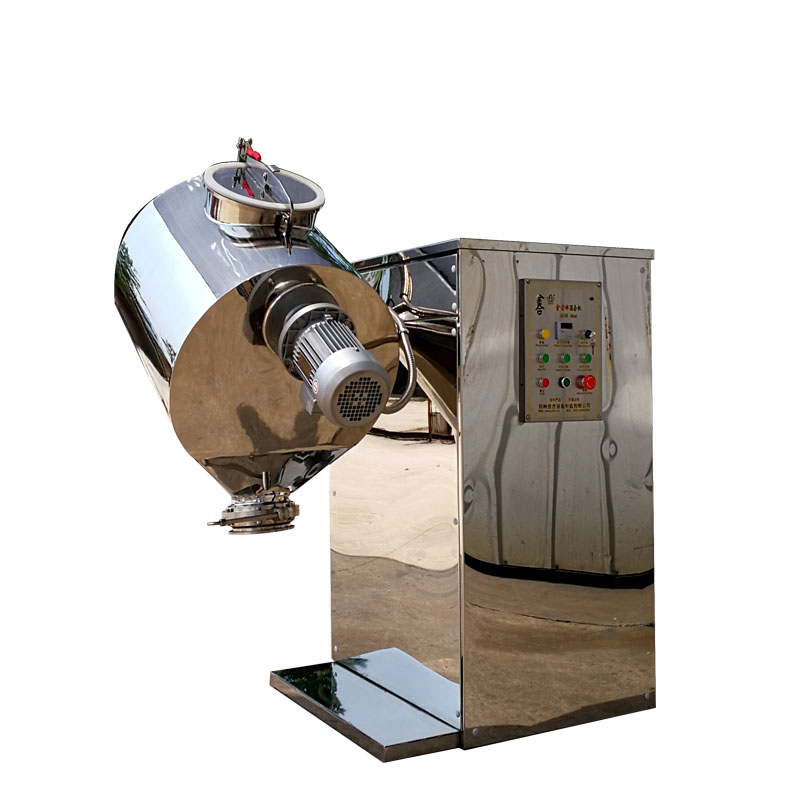

| Name | Drum replaceable powder mixer |

| Material | SS304,SS316 |

| Volume | 50-5000L |

| Suit | Powder mixture,liquid and powder mixer |

| Layer | Single Layer,Double Jacket For Electric or Steam or Hot Water For Heating |

| Dimension | can be customized |

| Function | mixing,blending,dispersing |

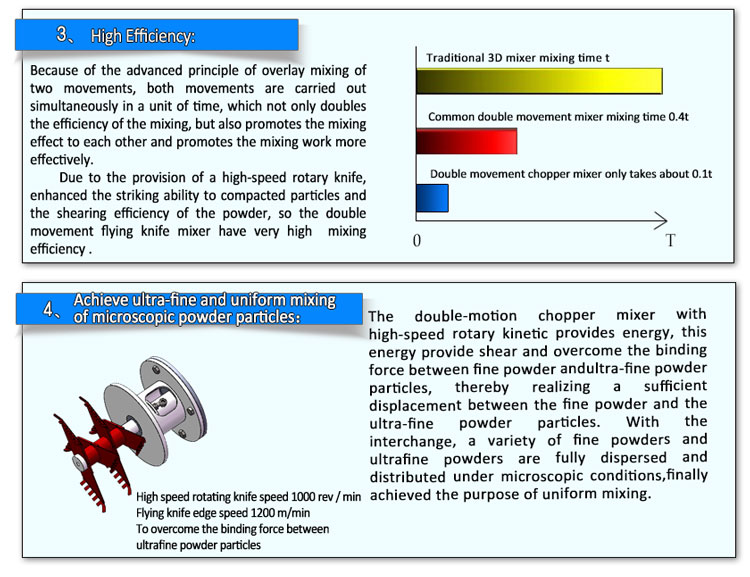

| Model | Vessel(L) | loading(L) | Running speed (r/min) | Chopper speed(r/min) |

motor(kw) | chopper knife(kw) | size(mm) |

| JHF20 | 20 | 12 | 25 | 950 | 0.75 | 0.37 | 960*435*987 |

| JHF50 | 50 | 30 | 25 | 950 | 1.1 | 0.55 | 1190*550*1232 |

| JHF100 | 100 | 60 | 21 | 950 | 1.1 | 0.55 | 1267*672*1407 |

| JHF200 | 200 | 120 | 16 | 950 | 1.5 | 0.75 | 1453*780*1590 |

| JHF400 | 400 | 250 | 15 | 950 | 2.2 | 1.1 | 1848*812*1772 |