Mixed volume of material:50L~10000L

Mixer power:2.2KW~45KW

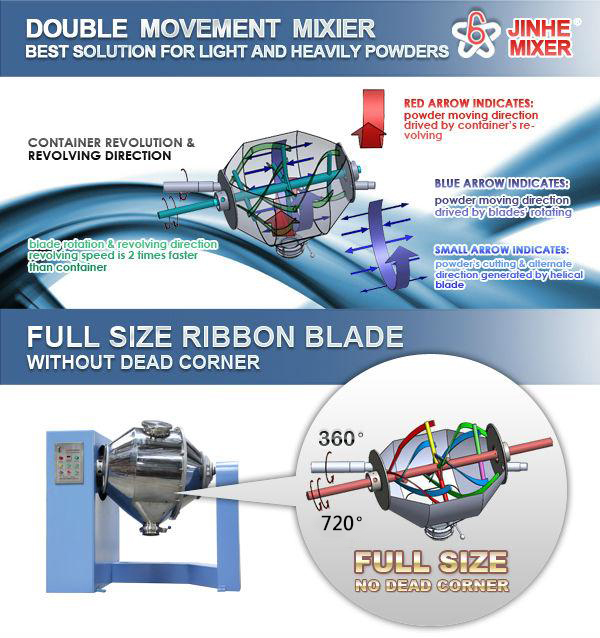

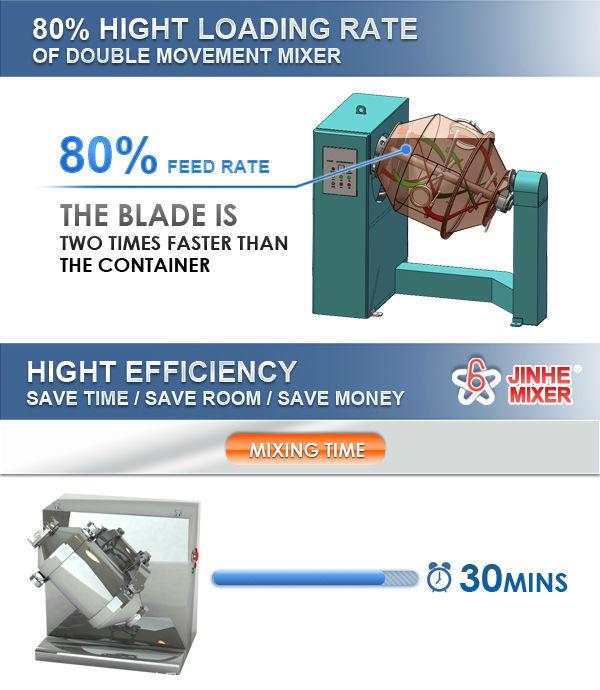

JINHE® JHX Double Movement Powder Mixer Machine is an advanced mixing machine which has proprietary intellectual property rights.

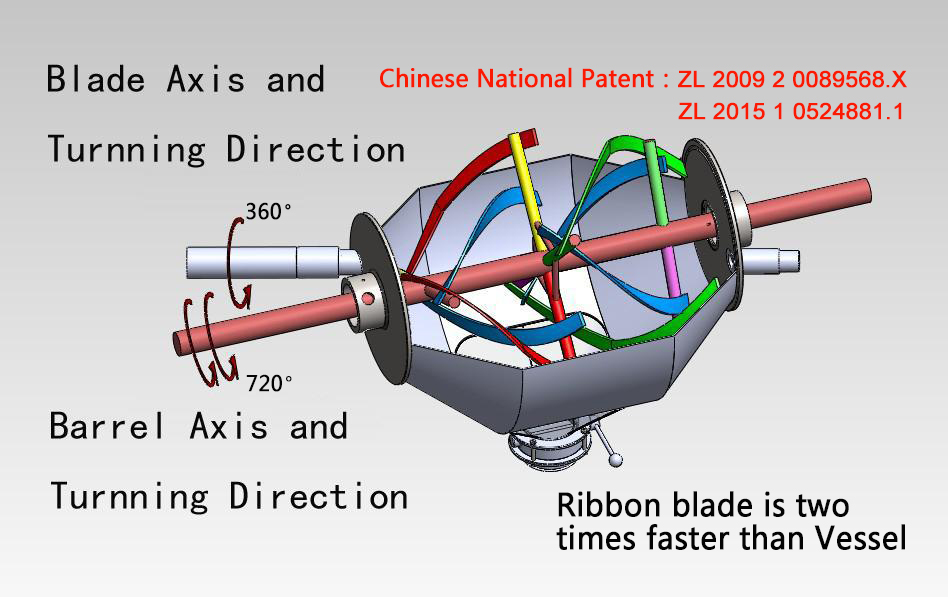

Our principle is make barrel turn around while full scale blade run independently. In addition, the barrel and blades turn around in different speed and different directions.

| Model | Max Capacity (L) |

Max Barrel Weight Capacity (Kg) |

Barrel Speed (r/min) |

Blade Speed (r/min) |

Motor Power (KW) |

Size(mm) | Weight (kg) |

| JHX50 | 40 | 60 | 25 | 50 | 1.1 | 1500*620*1000 |

430 |

| JHX100 | 80 | 110 | 23 | 46 | 1.1 | 1700*720*1200 |

500 |

| JHX200 | 160 | 240 | 21 | 42 | 2.2 | 2050*830*1400 |

660 |

| JHX400 | 320 | 500 | 17 | 34 | 3.0 | 2500*1010*1600 |

910 |

| JHX600 | 480 | 700 | 17 | 34 | 4.0 | 2700*1120*1750 |

1200 |

| JHX600Z | 480 | 1000 | 14 | 28 | 5.5 | 2700*1120*1750 |

1400 |

| JHX800 | 640 | 1400 | 14 | 28 | 5.5 | 2900*1200*1850 |

2000 |

| JHX1000 | 800 | 1800 | 11 | 22 | 7.5 | 3200*1300*2070 |

2300 |

| JHX1500 | 1200 | 2200 | 8 | 16 | 15 | 3200*1300*2070 |

2600 |

| JHX2000 | 1600 | 3600 | 6 | 12 | 18.5 | 3650*1500*2300 |

2900 |

| JHX3000 | 2400 | 4800 | 6 | 12 | 22 | 3800*2100*2900 |

3500 |

| JHX5000 | 4000 | 6000 |

5 | 10 | 30 | 4250*2350*3100 | 4500 |

| JHX7000 | 5600 | 9000 |

5 | 10 | 37 | 4750*2650*3750 | 7500 |

Double movement mixing machine inside helical blades and outside barrels movement picture.

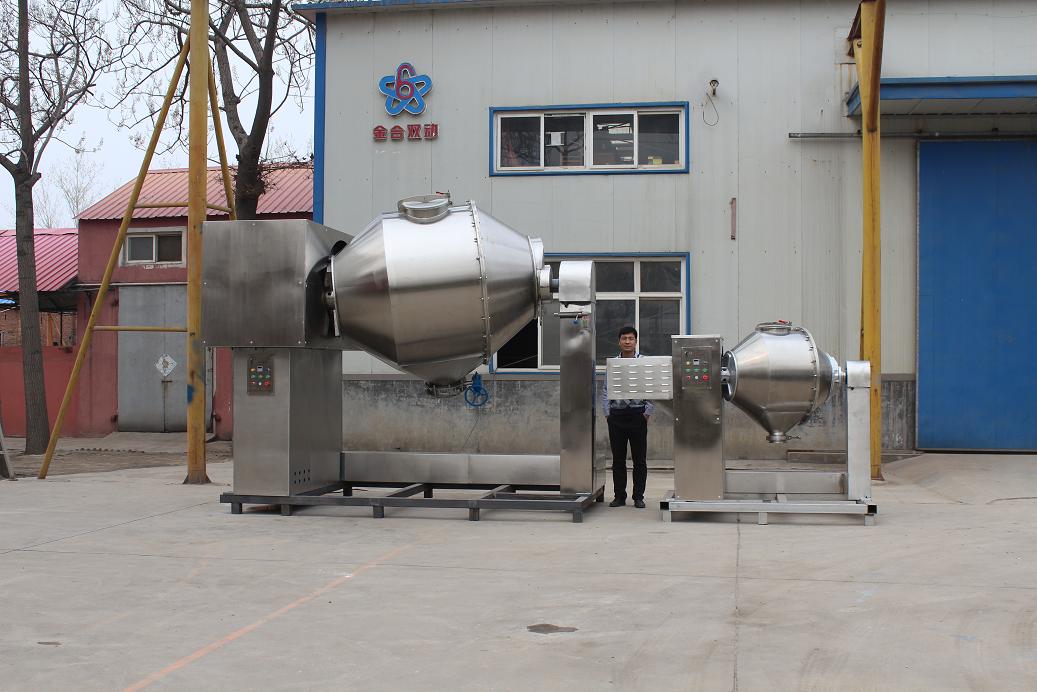

Transportation:

Ideal Mixing Effect: Due to the container revolving, the machine can mix more evenly in general points. While blades stirring, the machine can mix more meticulously and completely in detail points.