In order to guarantee the quality of product in production process,before mixing and after,we should ensure the powder's apparent density and particle diameter of the same or less variable(which is particularly important in powder metallurgy field).So it requires the movement for mixing equipment in the device cannot move too fast or intense,which destroys the original powder.Try to avoid movement in the following ways.

1)To deal with bad liquidity or to shatter the fake particles,people adding steel balls into the container.But the rolling ball will badly destroy the original powder.

2)Using the high speed rotating blade (the velocity of the tip linear is higher than 200m/min)to hammer the powder will also destroy the original powder.

3)Severely hit and shock motion during the mixing process will do destroy the original powder.

4)Because of select the wrong mixing machine,extending the mixing time when it's difficult to achieve purpose of uniform mixing, will also destroy the powder.

Thus,the ideal powder mixing process environment should be:

1)The motion device should at a moderate speed and continous and stable moved.

2)The movment of the powder should at a mild speed and in changeful direction.The powder groups were shunted,refined,recomposed, shunted,recomposed and repeated.And the thinner,the better.

3)With the aim to mixing uniformity,mixing time as short as possible.

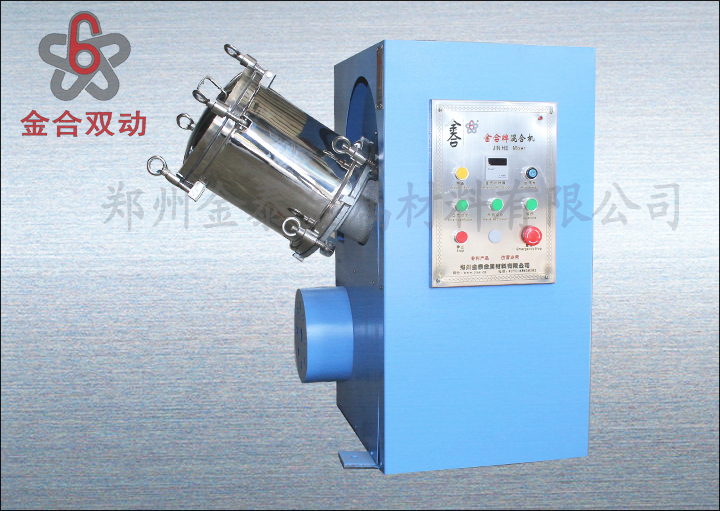

Our double movement powder mixer can easily achieve the ideal mixing effect.