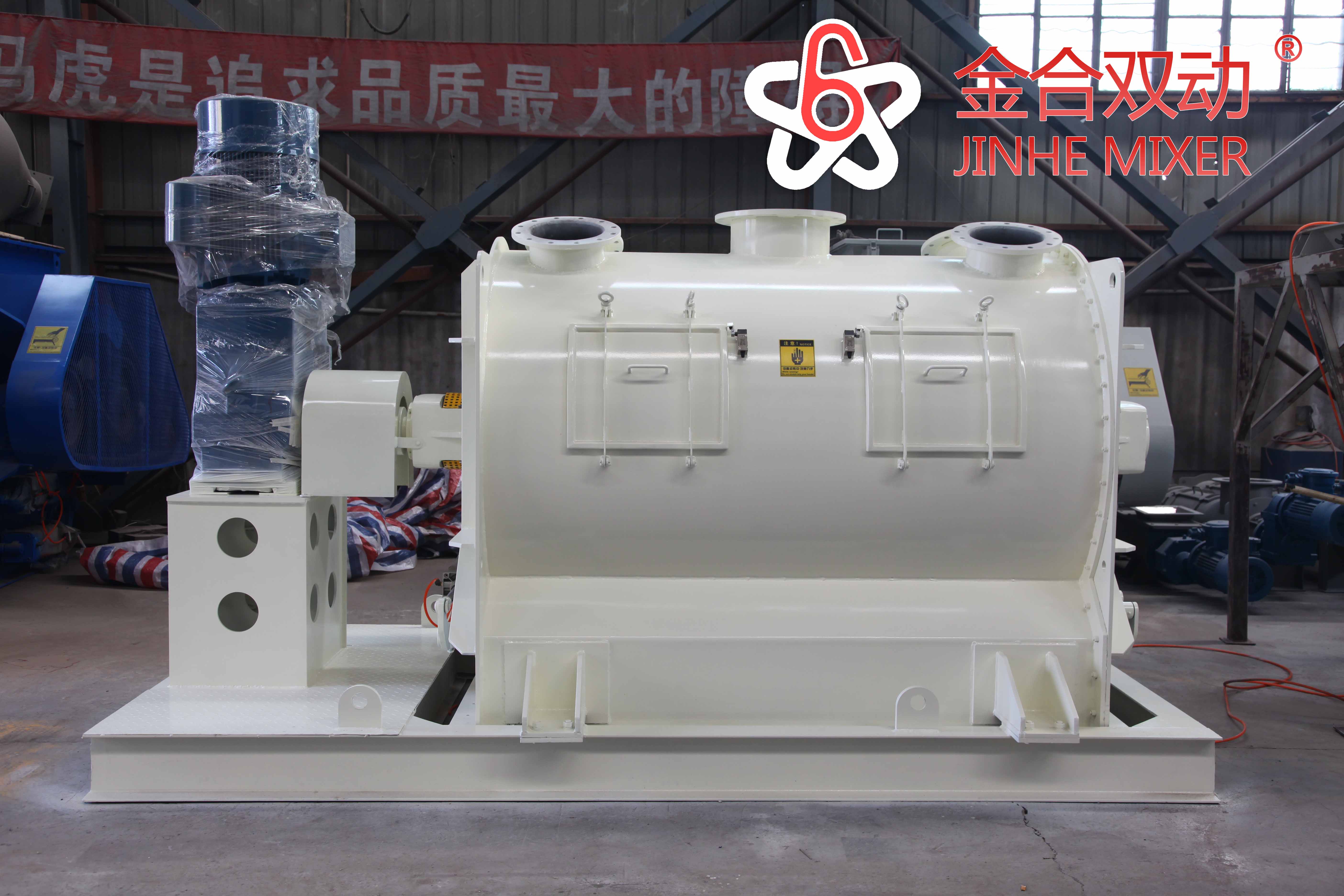

Coulter mixer machine mixing effect, not only on the speed of mixer coulter, and the coulter and the coulter mixer barrel size of the gap between the head, the length of the barrel of the case and other factors. Mixing output and power consumption of the spindle speed, the arrangement and quantity of the knife, the faster the speed, the more intense shearing action, the better crushing, production capacity will be increased. General mixing speed control when 1440 revolutions per minute in order to facilitate mixing. Flying speed is also not too fast to avoid heating the material, should control the temperature, the temperature is not too high, in order to select the control to make the material both to short mixing, but also in the mix does not adhere to the inner wall of the mixer machine is appropriate.

Mixer, in order to achieve good coulter mixer machine mixing effect, requires loading a loading capacity should be appropriate. Loading weight too much material in the coulter mixer because there is no adequate space for activities which affect the mixing effect and prolong the mixing time, increasing the power consumption; loading capacity is too small, also because coulter mixer machine the material is too small to form a sufficient resistance, thus weakening the mixing effect, extending the mixing time. Therefore, when the mixing operation the loading quantity and the material composition and properties of the machine structure, operation mode, the operating conditions and other factors.

General coulter mixer machine loading capacity and its working volume mixer machine relevant. Mixer operation control of process conditions, ie temperature and mixing time material control and material formulations generally relevant. Operation, that is, to mixing, but also to prevent the occurrence of molecular degradation of materials. Operation, usually by means of observation of the main motor ammeter readings change, to control the mixing operation process. Mixed operation is generally controlled at about 4-8mm. If the material during mixing general form of powder, slightly granular materials often need the help of Del mixer machine knife to chopped, crushed or diced so.