*

Double Movement means when the mixer working,full size 8 piece of helical blades revolving as well as the barrel.But their rotating direction and speed is different ,the blades revolving is 2 times faster than the container.These two mixing ways superposed together,that is why our machine has high efficiency and get ideal mixing effect.

Unique Advantages of Double Movement Mixer

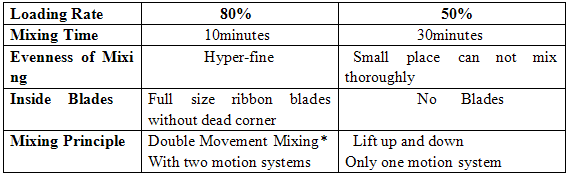

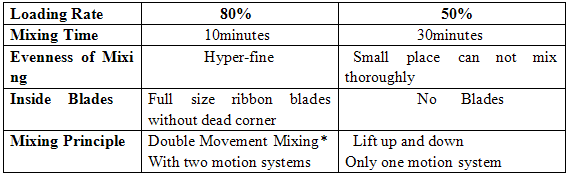

1.High Loading Ratio: Compared with ordinary 3D mixer, ours' loading ratio is much higher. Because blades take major role in machine working. That is why our double movement mixer's loading ratio is high, max. Loading rate can reach 80% of barrel. For the same volume, the loading capacity of our one machine is almost equivalent to two 3D mixers.

2.Ideal Mixing Effect: 100% no dead corner. Due to the barrel revolving, the machine can mix more evenly in general points. While blades stirring, the machine can mix more meticulously and completely in detail points.

3.Time-saving: The mixing way of our double movement mixer is two mixing ways superposed together, that is why our machine has high efficiency. Compared with 3D mixer, ours can save 60% time to meet mixing standard.

4.Money-saving:Compared with traditional mixer, ours can save time above 50%, save electricity about 70%, save space about 50%, money saving about 30%.

Compared Disadvantages of V Type Mixer

1.Small places like the corner can not mix thoroughly.

2.When you mix several kinds of powders,ultrafine powder and lightweight powder can not mix into the main powder thoroughly.It may effect the quality of your product.

3.Lifting action would cost high in consumption of electricity.

4.The V type drum lifting up and down may destroy the shape of the powder.