As is known to all, there are two extremes in every thing, especially in the mechanical manufacturing industry, the processing difficulty and the complexity of the technical implementation are greatly improved when the spare parts or mechanical equipment are very big or very small. For example, dry powder mixing machine manufacturing industry, equipment and means of improving the difficulty of processing, lathe, machining center corresponding to the machining accuracy is bigger, need a lot of special fixture to ensure the. Therefore, the market for the material mixed with the requirements of the mixed equipment, mostly small mixer (1000L the following equipment) to achieve. It can be said that before the advent of the dual movement of large dry powder mixing machine, the market is not the corresponding large-scale mixed fine powder equipment, is a large dry powder mixing machine to fill the gap, the need for large quantities of fine powder mixed industry, this has a landmark significance.

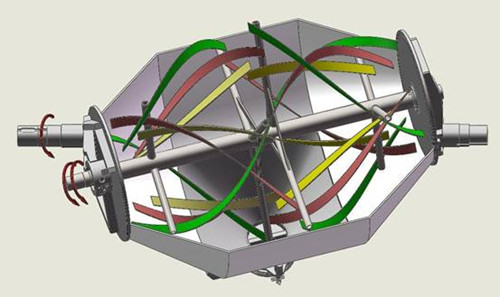

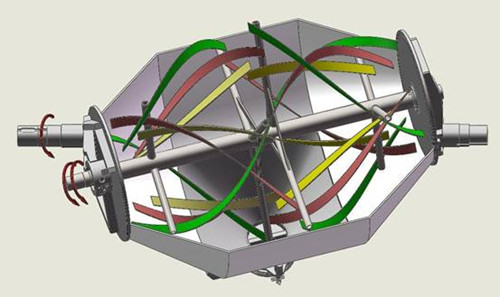

We all know that the same type of dry powder mixer, the larger the size of the device, the lower the mixing efficiency, and the more difficult to mix evenly. We may have such a question, our large dual motion dry powder mixing machine it's mixed evenly on what to protect, if it is the original technology, certainly mixed results do not work here, I solemnly introduce us to the large dual motion mixer is such as to achieve the fine mix of materials.

1, by increasing the density of the leaves, (for example, JHX600L is the 8 set of leaves, JHX2000L is the 16 set of blades), this increased the area of unit area and the powder contact, the unit time, increased with the number of powder particles, so as to achieve the purpose of fine mixing.

2, moderate speed, through repeated testing, select the best speed, speed stability, comprehensive consideration of the equipment to the selected cylinder edge along the barrel speed, centrifugal force and other factors, the company's Technology Department of the Kim several tests to find out the most scientific speed, fine material is mixed to achieve the best effect.

Therefore, the new type of double motion dry powder mixing machine of large mixed material does not mean that the uniformity will be reduced by taking the relevant technical measures, the same can be done with the fine mixture of materials.