Seven. What is the brand name of the structure of the compound machine?

Answer: manual on the clip type butterfly valve, sailing card (Shanghai set sail Valve Co., Ltd. production).

Eight. How do you add the liquid?

Answer: two kinds of ways to add optional:

1, static added, artificial from the feed port dumping;

2, the dynamic addition, the use of automatic spray device (side mixed side spray liquid).

If the use of automatic spray device, please verify the following questions: (1) the liquid viscosity and other physical characteristics, determine whether to suit the liquid; (2) how long the number of liquid spray.

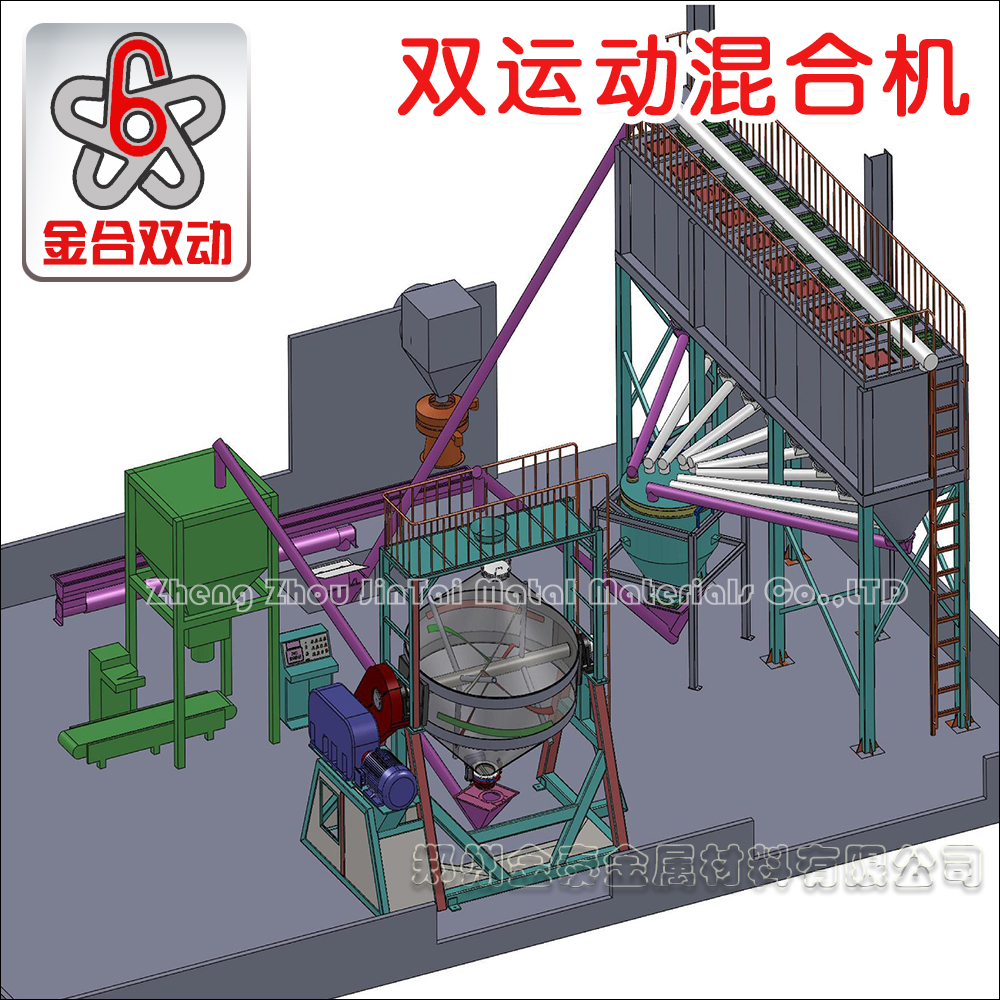

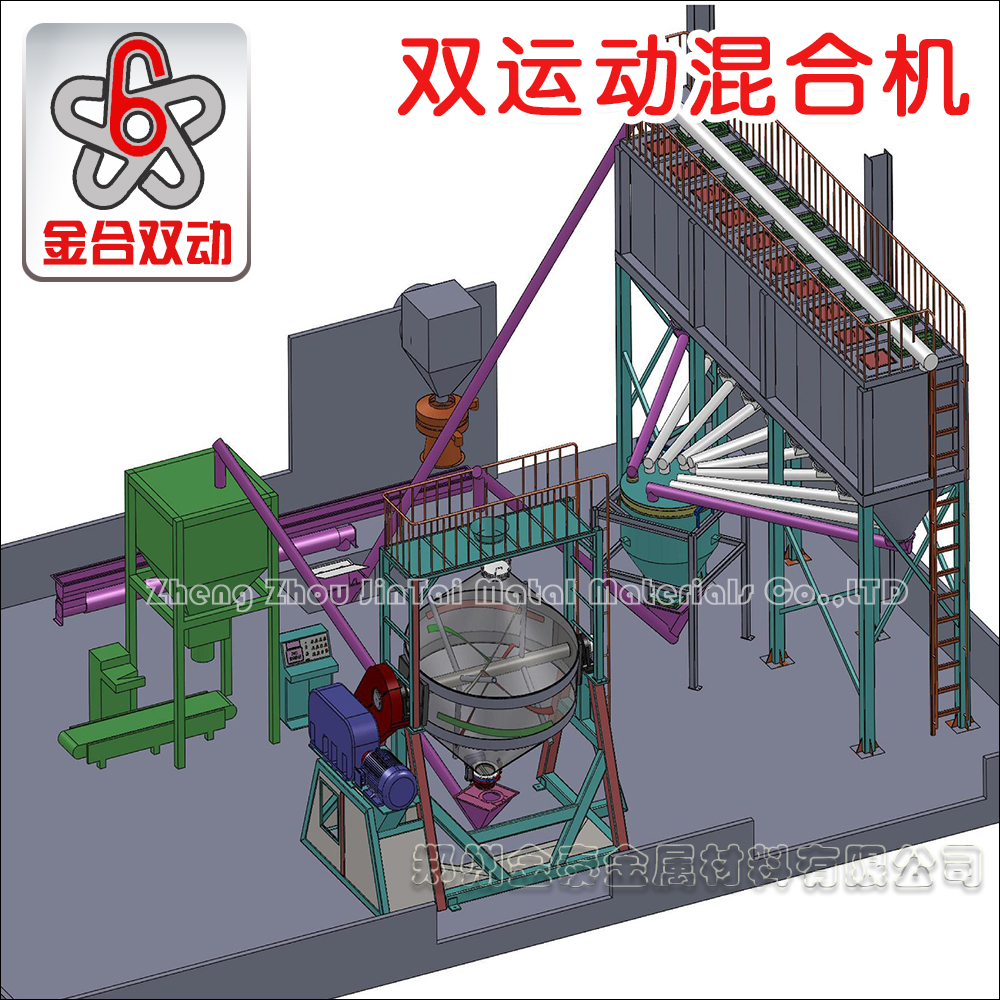

Nine. How to add the solid powder of the double motion dry powder mixer?

A: the equipment into the mouth from the ground height of 1.4m, three kinds of feeding methods:

(1) in the machine to build a small platform to reduce the height of the feed hole, the operator station on the platform of investment.

(2) a large platform is built on the top of the machine, and the material is suspended on the platform by the vehicle.

(3), the use of spiral feeding machine, bucket elevator or vacuum feeding machine, automatic transmission, mixer configuration automatically find positive, automatic docking function.

Ten, the heating principle of the double motion dry powder mixer? Life? How to change?

Answer: at one side of the mixer shaft end through the conductive slip ring to brush, with bolts will be electrically heated silica gel plate fixed on the mixing machine barrel, convenient replacement of the heating plate. According to customer needs with outer covering insulation layer, electronic control system can change the heating temperature. Can also set the temperature, the internal temperature of the mixing machine is heated to the set temperature automatically, and the temperature is lower than the setting temperature.

In the case of voltage temperature, the import of silica gel can be used for about four years.