Five, why the dual motion dry powder mixing machine is 70% of the loading rate, rather than the common 50%?

A: our equipment is different from the traditional dry powder mixing equipment market, the traditional dry powder equipment mixed mode: (1) the material barrel rotation, the use of space on the back mixing, (2) the material cylinder fixed purely rely on the blade mixing to mix. The single mode of motion determines that he needs to set aside a certain space for work, so the loading rate is low, the general loading rate is about 50%.

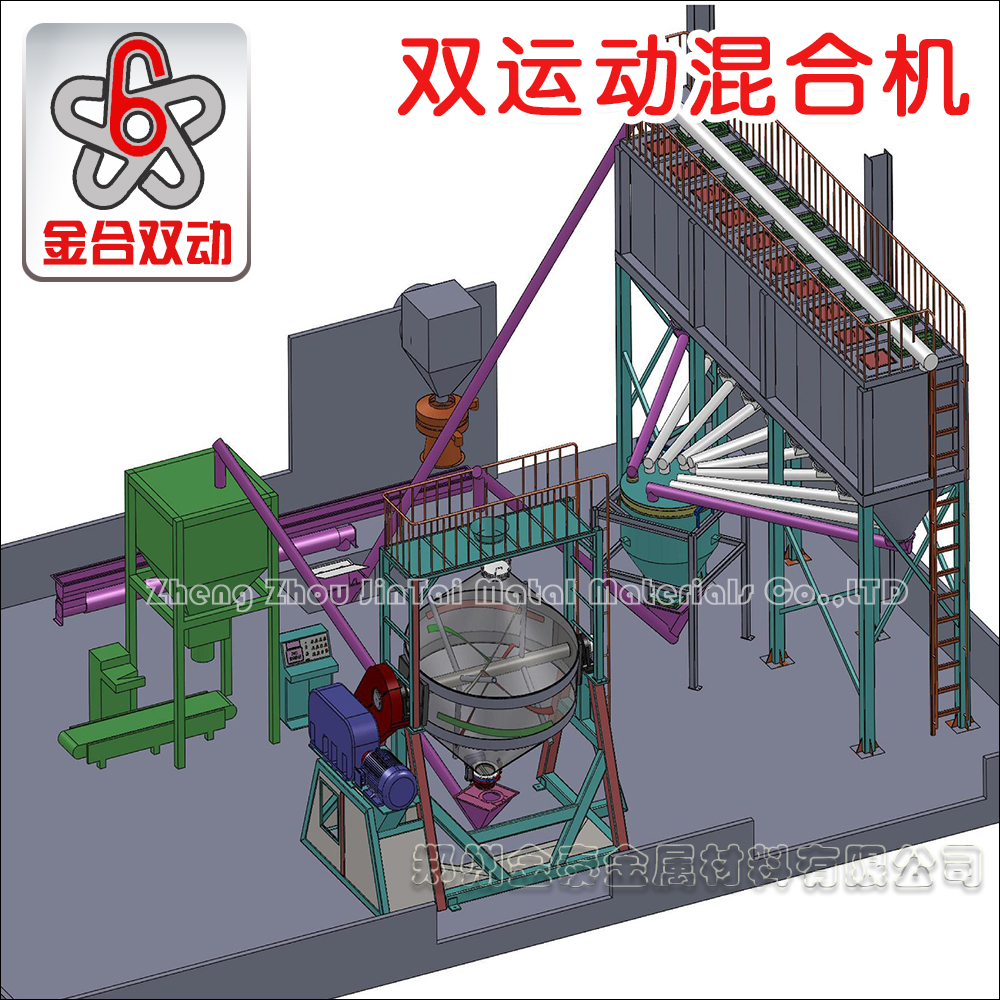

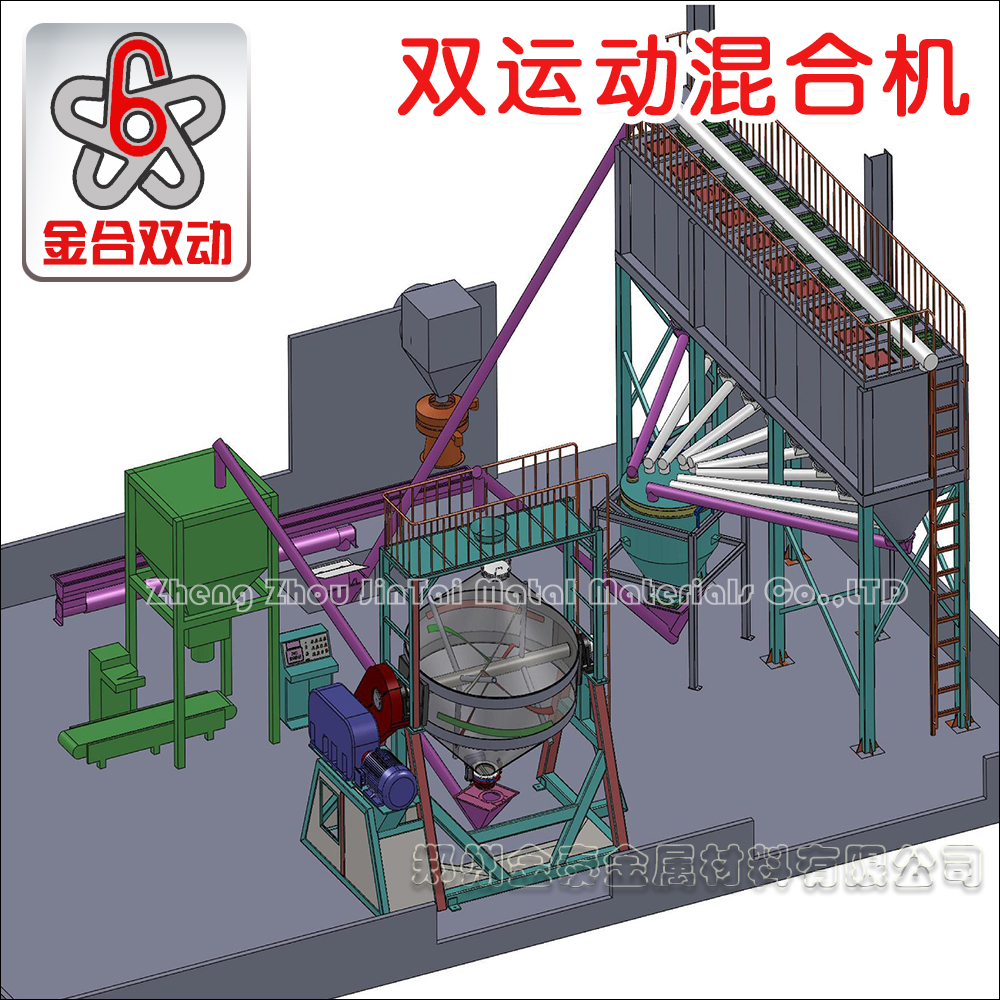

We double movement, dry powder mixing machine, a dynamic system and two sets of motion device, the motor drives the barrel rotation were mixed, and feed cylinder internal blade also in independently rotating, the superposition of two kinds of force on the material have coerced, convection, interspersed with the role, new sports insurance card 70% of the loading rate, at the same time, it can solve the problem of the proportion of the difference in the material not easily mixed, can also shorten the mixing time of a third,

Six, whether the dual motion dry powder mixer is considered in the wear resistance of the material.

A: we choose high quality 430 stainless steel, stainless steel series is the most wear-resistant model; the other two motion mixer in the mixing process is not like a screw with a mixing machine of the material can not turn, completely by the blade mixing to mix materials, so that the friction will be great. Double motion dry powder mixing machine mixing material of the material cylinder itself in operation, the internal screw with the blade of the powder is only an auxiliary shear, convection, friction is not, so the wear is very limited.

There are many success stories: Chongqing Huafu, Chongqing Zhibo, Chengdu days back to the powder metallurgy of leading manufacturers, mainly in the production of iron, copper based components using our equipment for two years did not appear barrel wear.

Also our equipment in the ultra hard material is applied on a large scale, the Yellow River cyclone, Aetna science and technology, Beijing Jingri, Guangdong Ben Lang, Quanzhou Zhongzhi, Hebei small bees, the industry benchmark for customer mix of the host material powder for a variety of diamond and metal powder, such a large mixed hardness material. There were no barrel wear phenomenon.