The homogeneous of the material mixing will affect the final quality of the products, which has been recognized by more and more manufacturers.

First, Pre mixing. When there is a very huge proportion of different materials, homogeneous mixed evenly on the problem, then you need to put some of the small number and main powder mixed with a small number, as a parent powder, mixed evenly mixed in proportion to a large number of mixed.

Second, improving the technology. The same product, the same composition, different enterprises to produce the product quality will have a greater difference, and the order of the investment has a certain relationship. Feeding, not simply the material throwing mixed into finished, also have strict requirements, which requires technical staff to continuously explore, develop a reasonable feeding sequence.

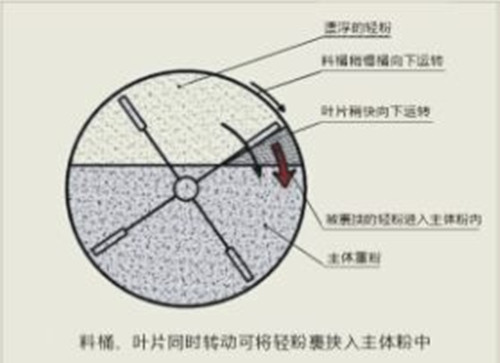

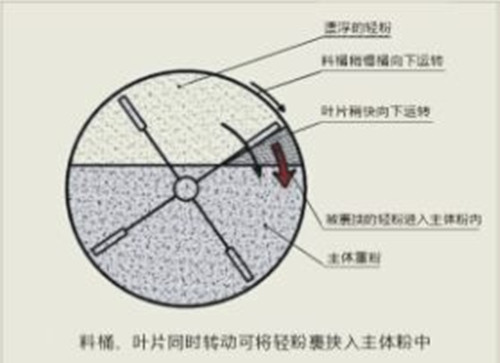

Third, the use of advanced mixing equipment to improve powders homogeneous. Double cone, V type, three-dimensional, trough and other mixing machine, are the use of several decades of philosophy, some of the use of the internal space of the material, the advantages of no dead ends, the disadvantage is low efficiency, high uniformity requirements of the material is not easy to mix; some are not transferred, the use of internal blade mixing, the disadvantage is that there is a dead end, the internal powder. Now there is a cross time product in the operation of the major companies, is a double motion mixer, double motion blending process. As the name suggests, is the equipment of a dynamical system, two sets of motion device, rotating cylinder let while the material convection, inner cylinder of full size leaf material also in independent rotary stirring, the superposition of two kinds of force of material have coerced force, can very easy to put the proportion differences larger small material coerced into the main body of the powder, uneven perfect solutions to the mixed problem. The device is considered a traditional device, the advantages of the development of the advantages of traditional equipment manufacturing.