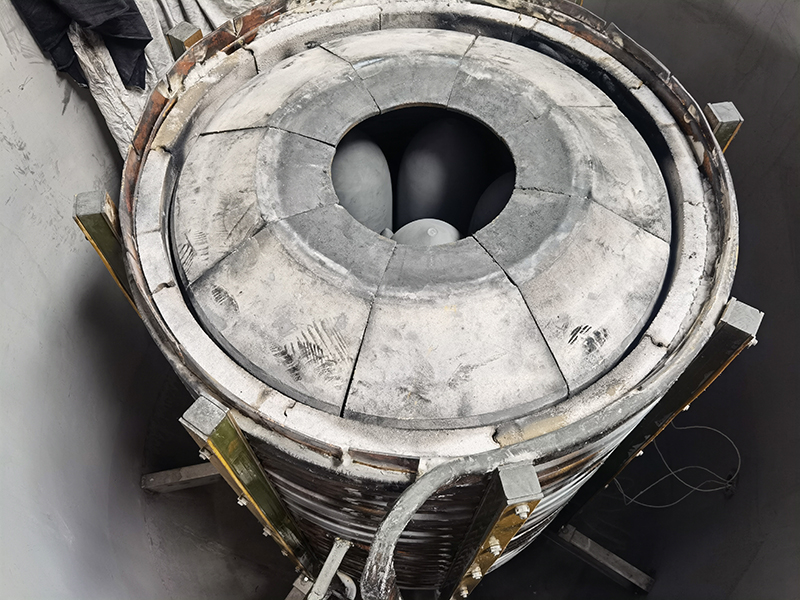

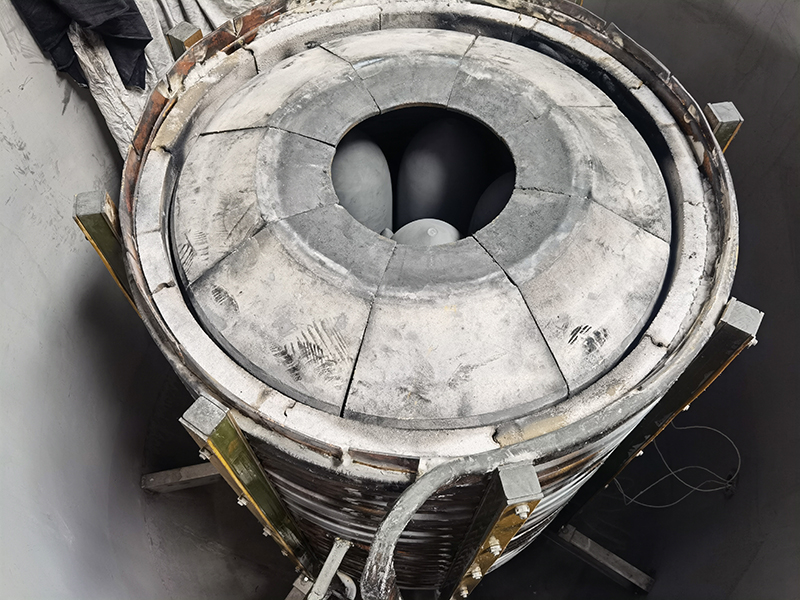

Industry Medium-Frequency Induction Furnace

The hydrogen protection sintering furnace is heated by induction in a hydrogen atmosphere, and uses the eddy current generated by electromagnetic induction as a heat source (electrical energy is converted into heat) to make the tungsten crucible in the coil generate high temperature, which is conducted to the workpiece through thermal radiation, thus in the powder metallurgy process Sintering the metal in the process. At the same time of heating, hydrogen can also reduce and purify the workpiece. This equipment is widely used in the powder molding and sintering industry of refractory metals such as tungsten, molybdenum and their alloys in enterprises, scientific research, and military units.

Performance characteristics:

1. The sintered product has uniform density, fine grains and low oxygen content.

2. High production efficiency and low sintering cost.

3. Fully automatic control, simple operation, automatic control by infrared temperature measurement and thermocouple continuous temperature measurement signal, and can be used continuously below 2300℃.

4. Multiple safety protections, real-time monitoring, explosion-proof devices, water shortage alarm devices, etc. are installed.

|

Model

|

Working zone

(mm)

|

Maximum temperature

(℃)

|

Temperature uniformity(℃)

|

Temperature accuracy

(℃)

|

Application temperature(℃)

|

Heating power

(kw)

|

|

JHB-06010

|

φ600*1000

|

2300

|

≤10

|

≤±1

|

2250

|

300

|

|

JHB-06511

|

φ650*1100

|

2300

|

≤10

|

≤±1

|

2250

|

400

|

|

JHB-065130

|

φ650*1300

|

2300

|

≤10

|

≤±1

|

2250

|

450

|

|

JHB-08012

|

φ800*1200

|

2300

|

≤10

|

≤±1

|

2250

|

500

|

|

JHB-08515

|

φ850*1500

|

2300

|

≤10

|

≤±1

|

2250

|

750

|

|

JHB-10036

|

φ1000*3600

|

2300

|

≤10

|

≤±1

|

2250

|

900

|